|

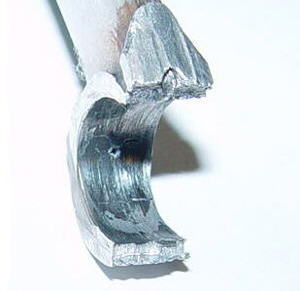

When the

tensile strength is lowered from heat the material breaks.

Another

scenario can also occur. The bushing can heat up the rod and

damage the heat treatment of the aluminum thus lowering the

strength. So the rod may not break when the damage occurred,

it happens when the rod is under extreme stress which the

rod could have handled if it was in its original heat treated

condition.

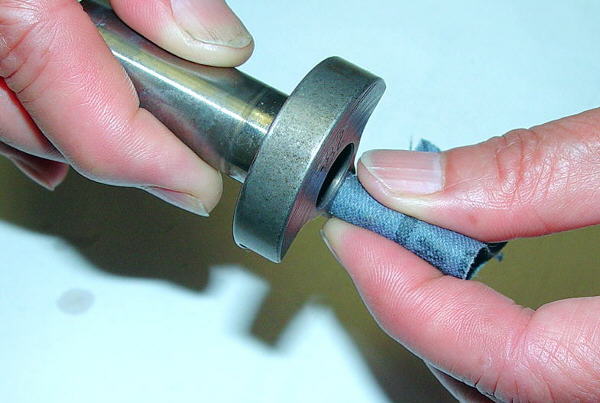

An another

possibility is the bushing could have spun just enough to

misalign the oil holes rendering them non functional. This

lack of oil will cause the overheating to occur when the rod/bushing

is stressed at high rpm... and here comes the break, for no

apparent reason.

|