|

Black

HP Tuned Pipes and Headers

|

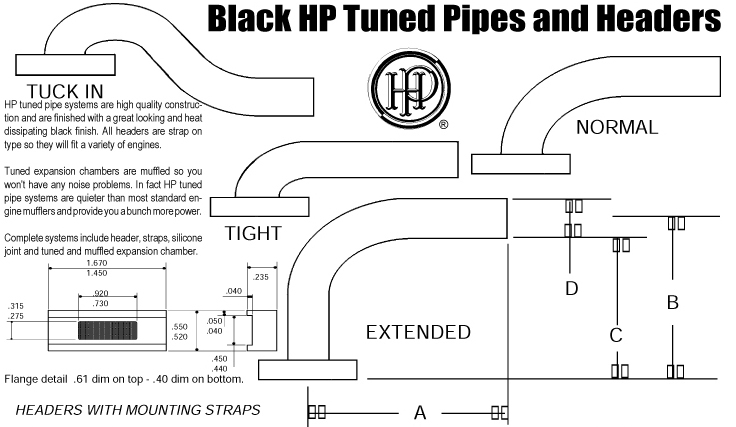

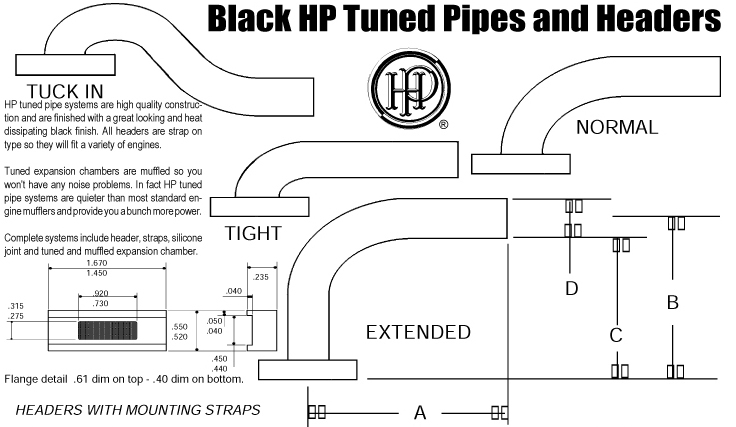

HP tuned pipe

systems are high quality construction and are finished with

a great looking and heat dissipating black finish. All headers

are strap on type so they will fit a variety of engines.

SPECIAL PRICES

.

|

|

Tuned expansion

chambers are muffled so you won't have any noise problems.

In fact HP tuned pipe systems are quieter than most standard

engine mufflers and provide you a bunch more power.

Weight of the

.40 pipe is 3.7oz and the .61 pipe is 5.5 oz.

|

|

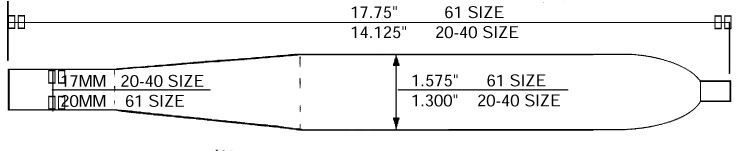

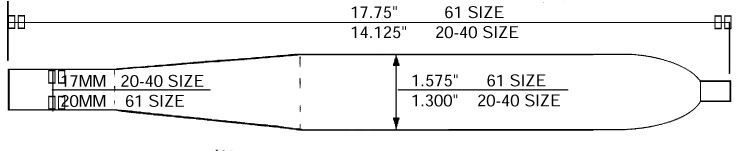

Tuned

pipe chamber for .40-.46 size part number HP TP40

Tuned

pipe chamber .61 size part number HP TP61

Header

Price includes header, straps. Silicone joint tube extra cost.

Click

for the whole list of HP headers and Pipes

| STYLE |

New

P/N |

FITS |

OLD

P/N |

A |

B |

C |

D |

Material |

| Tight

|

HPHD-614 |

HP

20, 40, ETC |

66111084 |

4.25

|

1.625* |

1.25 |

16MM

|

Steel |

| Tight |

HPHD-613 |

HP 20, 40, ETC |

66111083 |

4.0 |

1.75* |

1.375 |

16MM

|

Aluminum |

| Tight

|

HPHD-612 |

HP

20, 40, ETC |

66111082 |

4.125 |

1.0 |

0.7* |

16MM

|

Aluminum |

| Normal |

HPHD-622 |

HP

20, 40, ETC |

66211082 |

4.5 |

2.625* |

2.25 |

16MM

|

Aluminum |

| Normal

|

HPHD-624

|

HP

20, 40, ETC |

66211084

|

4.25 |

2.625*

|

2.25 |

16MM

|

Steel |

| Extended |

HPHD-625

|

HP

20, 40, ETC |

66211085

|

4.5 |

3.5 |

3.25* |

16MM |

Steel |

| Extended |

HPHD-623 |

HP

20, 40, ETC |

66211083 |

4.25 |

4.25 |

4.00 |

16MM |

Aluminum |

| |

|

|

|

|

|

|

|

|

| Normal

|

HPHD-822 |

HP

20, 40, ETC |

86211082 |

4.25 |

2.75 |

2.5* |

18MM |

Aluminum |

| Normal |

HPHD-815 |

HP

20, 40, ETC |

86111085 |

4.25 |

2.75 |

2.5 |

18MM |

Steel |

| Extended

|

HPHD-818 |

HP

20, 40, ETC |

86111088 |

4.25

|

3.5 |

3.125* |

18MM

|

Steel |

| Extended

|

HPHD-823 |

HP

20, 40, ETC |

86211083 |

4.5 |

3.5 |

3.125* |

18MM |

Aluminum |

| Extended

|

HPHD-825 |

HP

20, 40, ETC |

86211085 |

4.25 |

3.525 |

3.275 |

18MM |

Steel |

| |

|

|

|

|

|

|

|

|

| Tuck

in |

HPHD-686

|

HP

61, HB 61, OS FSR 61, ETC |

66311086

|

4.75 |

-1.00 |

|

19MM |

Aluminum |

| Normal |

HPHD-834 |

HP

61, HB 61, OS FSR 61, ETC |

86311084 |

4.25 |

2.625 |

2.2 |

20MM |

Aluminum |

| Extended |

HPHD-935 |

HP

61, HB 61, OS FSR 61, ETC |

96311085 |

4.25 |

3.375* |

3.00 |

20MM |

Steel |

All measurements are approximate.

|

Instructions

on

HOW TO TUNE A TUNED PIPE

|

| |

|

The

HP TUNED PIPE SILENCER offers good exhaust muffling combined

with considerable power increase to satisfy both environment

protection considerations and the modelers demand for more

power. In the 12.000-16.000 R.P.M. range, the HP TUNED PIPE

SILENCER gains up to 1700 R.P.M. for your HP engine when compared

to the standard silencer and up to 1000 R.P.M. when compared

to the engine without silencer. The power increase is achieved

by making better use of the combustible mixture.

Working principle of the tuned pipe... When the engine is

operated with a standard silencer or without silencer, losses

of unburnt mixture during the exhaust stroke occur. Therefore,

the ensuing working stroke can use only the remaining part

of the mixture to produce power. In the tuned pipe, cyclic

pressure waves develop due to reflection of the exhaust gases

by a baffle. During this "supercharging" process, unburnt

mixture normally lost through the exhaust is returned into

the combustion chamber thus improving the volumetric efficiency

of the engine. The HP TUNED PIPE SILENCER yields this effect

even without being matched to the operating conditions. For

obtaining the full potential power gain, however, it is necessary

to tune the ENGINE-TUNED PIPE SILENCER system precisely to

existing operating conditions This is easily achieved by adjusting

the manifold length. The HP manifolds are delivered with excessive

length, and have to be shortened to suit the operating conditions.

|

| |

|

TUNING

THE HP TUNED PIPE SILENCER |

| |

For

tuning, a precision tachometer and two props of the

same type with identical diameter, but with pitch differing

by about one inch, are needed, for example.

For .61 engines --- 11x6 and 11x7 or 11x7 and 11x7.75

For .40 engines --- 10x5 and 10x6

In flight, the engine's speed is higher by about 1000

R.P.M. (depending on the model's velocity) when compared

to a static R.P.M. with identical prop. For exact

tuning on the bench, a prop should be used which has

static R.P.M. coinciding with flight R.P.M. of the

prop to be used on the model (for example, if 11 x

7 is the flight prop, use an 11 x 6 for tuning). When

cutting down the manifold outlet (in 1/4" steps),

R.P.M. will go up gradually. When no additional R.P.M.

increase occurs, the length of the system is correct.

Any further shortening of the manifold will decrease

R.P.M.

Small deviations from the correct length can be compensated

by adjusting the silicone tube, which also depends

on the type and brand of propeller. The graph shows

the principal form of the power curve.

|

|

|